Quality assured body work is a cornerstone for vehicle collision repair centers, ensuring customer satisfaction and vehicle safety through systematic quality control (QC). This process involves visual inspections, functional tests, and adherence to industry protocols by trained technicians. Top-tier centers prioritize standardized procedures for consistent results, minimizing errors and enhancing their reputation. Continuous improvement through advanced tools and techniques, including digital QC systems and regular staff training, drives exceptional service, boosts customer satisfaction, and cultivates loyalty.

In the competitive automotive repair industry, maintaining consistent quality assured body work is paramount to customer satisfaction and business success. This article delves into the intricate world of quality control management within body work repair centers, exploring essential strategies for ensuring superior results. From understanding foundational quality control basics to implementing standardized procedures and fostering continuous improvement, we uncover best practices that elevate the craftsmanship of body work repairs, ultimately enhancing customer trust and retention.

- Understanding Quality Control Basics in Body Work Repair

- Standardized Procedures for Consistent Quality Assured Results

- Continuous Improvement: Tools and Techniques Employed

Understanding Quality Control Basics in Body Work Repair

Quality Control (QC) is a fundamental aspect of ensuring quality assured body work in vehicle collision repair centers and auto collision centers. It involves a systematic process to evaluate and maintain the standards of repairs conducted on damaged vehicles, such as cars or trucks. The primary goal is to identify and rectify any deviations from established procedures, ultimately guaranteeing customer satisfaction and the safety of repaired vehicles.

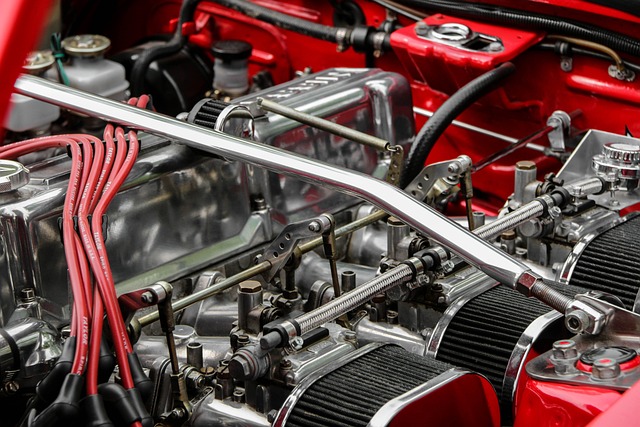

In the realm of body work repair, QC processes include visual inspections, functional tests, and adherence to industry-standard protocols. Trained technicians conduct meticulous assessments to verify the accuracy of repairs, ensuring that car damage repair meets the required specifications. This involves checking alignment, paint job quality, and structural integrity, among other factors. By implementing robust QC measures, body work repair centers can maintain their reputation, ensure customer trust, and prevent costly rework or safety hazards associated with substandard vehicle collision repair.

Standardized Procedures for Consistent Quality Assured Results

At top-tier body work repair centers, managing quality assured body work involves implementing standardized procedures that serve as a foundation for consistent results. These protocols ensure every step of the repair process—from initial assessment to final inspection—meets or exceeds industry standards. By establishing clear, detailed guidelines, centers can minimize errors and inconsistencies, delivering high-quality finishes that satisfy customers and build reputational capital.

Standardized procedures facilitate effective communication among staff, streamline workflows, and promote a culture of quality within the repair facility. Whether focusing on collision repair services, vehicle restoration, or fleet repair services, these protocols ensure that every technician follows the same meticulous approach, resulting in reliable and consistent outcomes for all types of body work.

Continuous Improvement: Tools and Techniques Employed

In the realm of quality assured body work, continuous improvement is a cornerstone strategy for top-tier vehicle repair services and vehicle body shops. These centers leverage advanced tools and techniques to elevate their standards and meet the evolving needs of customers. One key technique involves implementing digital quality control systems that streamline processes and ensure precision in car damage repairs. Automated measurement tools, for instance, help in accurately assessing and documenting repairs, minimizing human error and maximizing consistency.

Moreover, continuous improvement in body work repair centers often includes regular staff training sessions to update skills and knowledge. By staying abreast of the latest industry standards and technologies, such as advanced paint matching techniques and state-of-the-art welding equipment, these shops can deliver exceptional vehicle body shop services. This commitment to ongoing development not only ensures high-quality repairs but also fosters customer satisfaction and loyalty among those seeking car damage repair solutions.

In managing quality control at body work repair centers, a holistic approach combining standardized procedures, continuous improvement techniques, and an emphasis on quality assured body work is paramount. By implementing these strategies, repair centers can ensure consistent, reliable results that meet or exceed customer expectations. This not only fosters trust but also drives business growth in today’s competitive market.