In electric and hybrid vehicle maintenance, Quality Assured Body Work (QABW) is crucial for safety and performance. Stricter protocols ensure precise repair using advanced materials and techniques, addressing collision damage while preserving structural integrity, environmental compatibility, aesthetics, and functionality, catering to the specialized needs of these advanced vehicles' owners.

In the rapidly evolving automotive landscape, ensuring top-tier quality in vehicle construction is paramount, especially for electric and hybrid vehicles. This article explores the concept of quality assured body work, delving into the unique standards and considerations that define this specialized craft. We’ll uncover the special challenges posed by electric and hybrid powertrains and how modern techniques and materials contribute to the longevity of these innovative vehicles.

- Understanding Quality Assured Body Work Standards

- Special Considerations for Electric and Hybrid Vehicles

- Ensuring Longevity: Techniques and Materials Used Today

Understanding Quality Assured Body Work Standards

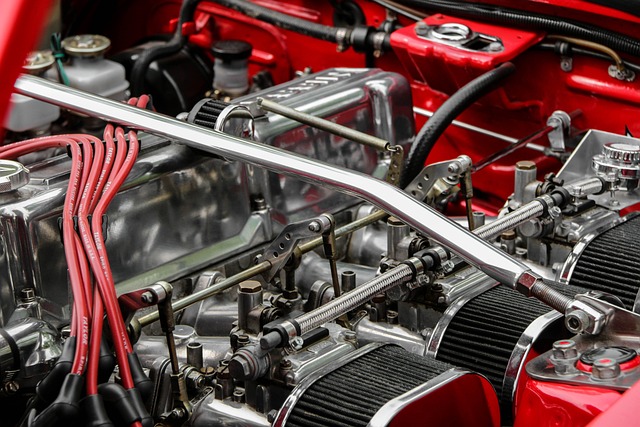

In the realm of electric and hybrid vehicle maintenance, Quality Assured Body Work (QABW) stands as a cornerstone for ensuring safety and optimal performance. These vehicles, with their advanced propulsion systems, demand meticulous care during repairs or restoration to preserve structural integrity and environmental compatibility. QABW standards dictate rigorous protocols for car collision repair, auto glass replacement, and overall body panel refurbishment, guaranteeing both aesthetic perfection and the highest level of safety.

Adherence to these stringent guidelines is crucial in mitigating potential risks associated with the unique construction of electric vehicles. Every aspect, from precise alignment of body panels to expert handling of sensitive electrical components during car collision repair, must meet defined criteria. Such meticulous attention ensures not just a visually appealing car restoration but also a vehicle that functions seamlessly, maintaining the advanced technology and eco-friendly credentials that define these modern modes of transport.

Special Considerations for Electric and Hybrid Vehicles

When it comes to quality assured body work for electric and hybrid vehicles, unique considerations come into play due to their advanced technology and specialized components. These vehicles often feature lightweight materials, intricate electrical systems, and high-performance batteries that require meticulous care during any repair or restoration process. Auto glass replacement, in particular, demands precision to maintain the vehicle’s aerodynamic efficiency and ensure driver safety.

Fender repair and other body shop services for electric/hybrid cars must consider the potential impact on energy efficiency and environmental sustainability. Skilled technicians employ specialized techniques and tools to minimize damage to sensitive parts while effectively fixing or replacing components like fenders, panels, and doors. This meticulous approach not only guarantees a visually appealing finish but also ensures the vehicle retains its optimal performance and range, making it crucial for satisfied electric/hybrid vehicle ownership.

Ensuring Longevity: Techniques and Materials Used Today

In the realm of electric and hybrid vehicles, ensuring longevity through quality assured body work is paramount. Modern techniques and materials play a crucial role in preserving the integrity and performance of these advanced automobiles. Specialized coatings and adhesives, for instance, are designed to withstand the unique challenges posed by electric motors and lithium-ion batteries, preventing corrosion and ensuring structural stability over extended periods.

Furthermore, the use of precision manufacturing processes guarantees precise alignment and fitting of body panels, enhancing overall vehicle aesthetics and aerodynamic efficiency. Advanced welding technologies also contribute significantly to durability, creating seamless bonds that can withstand rigorous testing for safety and reliability. Today’s luxury vehicle repair services often incorporate these cutting-edge practices, offering car bodywork services that not only restore but also elevate the performance and value of electric and hybrid vehicles.

In conclusion, adopting quality assured body work standards is paramount in the manufacturing of electric and hybrid vehicles. By understanding and adhering to these stringent requirements, manufacturers can ensure the longevity and superior performance of these vehicles. The unique considerations and advanced techniques discussed in this article highlight the evolving landscape of automotive craftsmanship, particularly tailored for the demands of today’s eco-friendly transportation solutions.