Quality assured body work restores vehicles to OEM specifications after damage, ensuring structural integrity, safety, and aesthetic appeal through precise repairs using advanced tools and rigorous testing, maintaining original value and peace of mind for customers.

In today’s automotive landscape, maintaining Original Equipment Manufacturer (OEM) specifications is paramount for vehicle performance and safety. Quality Assured Body Work (QABW) plays a pivotal role in restoring these precise standards after repair or reconstruction. This article delves into the intricate process of QABW, highlighting its importance in achieving OEM accuracy. We’ll explore how rigorous testing and validation ensure every component meets the exacting standards required for top-tier vehicle functionality.

- Understanding OEM Specifications and Their Significance

- The Role of Quality Assured Body Work in Restoration

- Ensuring Precision and Consistency Through Testing and Validation

Understanding OEM Specifications and Their Significance

OEM (Original Equipment Manufacturer) specifications represent the precise standards and guidelines set by automotive manufacturers for their vehicles’ components, including body panels, frames, and systems. These specifications are crucial as they ensure that every part of a vehicle functions optimally, providing safety, reliability, and performance. When it comes to body work, maintaining these OEM standards is essential for several reasons. Quality assured body work aims to restore not just the physical appearance but also the structural integrity of a vehicle, ensuring it meets these OEM benchmarks.

For instance, consider auto glass replacement, where the new glass must precisely fit the frame and align with the vehicle’s design. Similarly, in vehicle collision repair or car dent repair, technicians must carefully follow OEM guidelines to ensure the repaired areas are structurally sound and seamlessly integrate with the rest of the vehicle. This attention to detail guarantees that the restored vehicle not only looks like its original state but also behaves as designed, enhancing safety and driving dynamics.

The Role of Quality Assured Body Work in Restoration

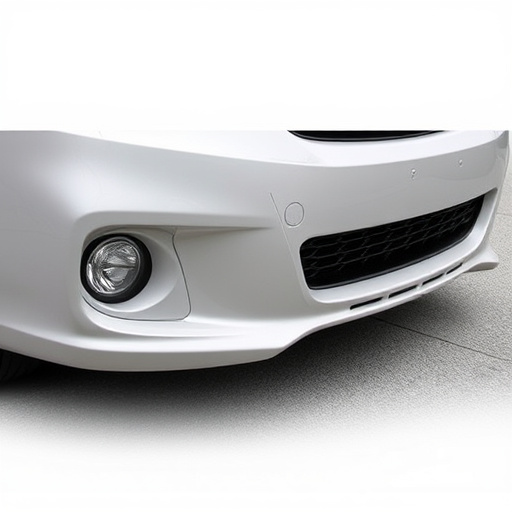

Quality assured body work plays a pivotal role in restoring vehicles to their Original Equipment Manufacturer (OEM) specifications after damage. In the event of a fender bender or other car dent removal needs, skilled technicians employ meticulous techniques and high-quality materials to ensure precise repairs that maintain the vehicle’s structural integrity and aesthetic appeal. This meticulous process involves not just auto glass replacement but also careful handling of panels, frameworks, and finishes to match the OEM’s exact standards.

The restoration process begins with a comprehensive assessment of the damage, followed by disassembly, repair or replacement of affected components, and meticulous reassembly. Quality assured body work guarantees that every step is performed with precision and adherence to strict quality control measures. This ensures not just visible repairs but also long-lasting durability, enhancing safety features and overall vehicle performance.

Ensuring Precision and Consistency Through Testing and Validation

In the realm of quality assured body work, precision and consistency are paramount to restoring Original Equipment Manufacturer (OEM) specifications. Rigorous testing and validation protocols play a crucial role in ensuring that every repair, whether it’s fender repair, hail damage repair, or vehicle collision repair, meets the exacting standards set by the automotive industry. This meticulous process involves using advanced diagnostic tools and specialized equipment to verify the accuracy of repairs, guaranteeing that each vehicle returns to its pre-incident condition.

By implementing comprehensive testing procedures, body shops can maintain a high level of consistency across all repairs. This includes visual inspections, computer-aided measurements, and functional tests to ensure every component is restored to OEM specifications. Such attention to detail not only guarantees the safety and performance of the vehicle but also preserves its original value and appearance, providing customers with peace of mind that their vehicles are in excellent hands.

Quality assured body work plays a pivotal role in restoring vehicles to their original equipment manufacturer (OEM) specifications. By understanding the significance of these standards, employing meticulous restoration techniques, and ensuring precision through rigorous testing, professionals can deliver superior results. This comprehensive approach guarantees that vehicles not only look new but also perform optimally, providing drivers with a reliable and safe driving experience.